What Is the Role of High-Tech Air Distribution in Critical Environments?

Air Distribution Systems Protect Personnel and Safeguard Assets

Air distribution is essential for industries with critical environments. High-tech air distribution systems and products deliver clean, conditioned air, which is essential for effective operations.

The need for air distribution capabilities has continued to grow. Increased demand means these products play an ever-evolving role in critical environments.

What Is a Critical Environment?

A critical environment is a catch-all term for commercial spaces that require specific environmental conditions to maintain processes. Environmental criteria may include:

- Humidity levels.

- Reduced contaminant levels.

- Air temperature.

- Air pressure.

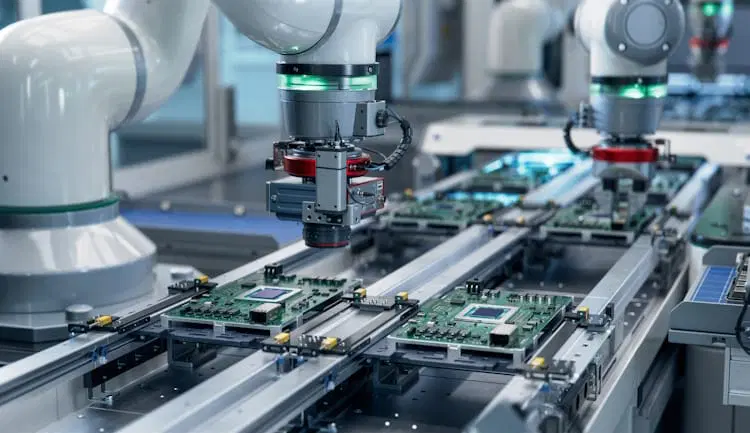

Industries such as microchip fabrication, health care, pharmaceuticals, and biotechnology depend on critical environments.

Why Do High-Tech Air Distribution Products Matter for Critical Environments?

Businesses with critical environments depend on air distribution systems and products to create the environmental conditions required for their industry-specific operations and processes.

While a hospital operating room might depend on air distribution products to protect patients and health care professionals from infection, a microchip plant must guard against dust landing on sensitive components, such as silicon.

Facilities with critical environments can’t afford to risk infection or product contamination. Air distribution mitigates risk and protects business interests.

How Air Distribution Provides Support for Critical Environments

Several air distribution products create and maintain industry-specific environments.

- Fan filter units (FFUs): These systems provide fresh, filtered air or remove unfiltered air from a room. FFUs are powered by a motor for airflow and are equipped with a HEPA or ULPA filter, which blocks particles from entering or remaining in the space.

- Diffusers: Diffusers deliver precise, directional airflow into a critical environment, such as an operating room.

- Grilles: Return and supply grilles use blades in various geometries and angles to control air volume and pressure in a critical environment.

- Humidifiers and dehumidifiers: Commercial versions of these products ensure humidity levels are appropriate for critical environment processes.

- Sensors, monitors, and controls: These devices capture and report on environmental metrics, such as humidity, and allow personnel to adjust levels inside or outside the space.

Current High-Tech Air Distribution Technologies Driving Results for Critical Environments

A tour of any HVAC conference exhibition hall will reveal the sheer volume of air distribution technologies in today’s market.

Many of these technologies are new takes on tried-and-true air distribution methods. However, these high-tech offerings significantly improve on standard air distribution for critical environments:

- Turnkey systems: Air distribution manufacturers make the installation and operation of their critical environment products as convenient as possible. They can ship their products in sections directly from their facility, so the equipment can be assembled quickly without exposure to dust, debris, and other unnecessary materials on the construction site.

- Comprehensive ceiling grids: Air distribution systems are often installed in ceiling grids, accommodating several products, including rows of FFUs, lighting, and access panels. The most customized versions consider industry-specific needs, such as additional equipment mounting for medical personnel during surgery.

- Network communication: FFUs and other products can be outfitted for building automation and control (BAC) and other building automation systems (BAS). This functionality allows facility teams to remotely control air distribution products, protect them from cyberattacks, and monitor their performance in real-time.

- Portable solutions: Although FFUs have been providing air distribution for critical environments since the 1980s, these systems have evolved to provide better performance specs, including versatility and flexibility about where they are used. Facilities can target a particular space, such as a single patient recovery room, with movable, compact FFUs.

- Artificial intelligence integration: Although AI capabilities are new to the critical environment market, automating processes, interpreting data, and making adjustments with the support of this burgeoning technology promise to make maintaining a critical environment easier than ever. AI may also help with resource management to meet energy efficiency standards for organizations committed to sustainability.

Air Distribution Systems and Products Are Vital Infrastructure

For industries that require stringent environments to protect people and processes, a facility isn’t complete until air distribution products are chosen.

Air distribution and filtration are as essential for critical environments as any major facility infrastructure. A partnership with an air distribution team is an essential strategy to prepare your facility for success. If your facility’s bottom line depends on critical environments, air distribution manufacturers can help you select effective products. Manufacturers offer a depth of experience with your industry’s air distribution requirements, along with product customizations that benefit business-specific needs.

Continue exploring the relationship between air distribution and critical environments, starting with this article, which describes the benefits of including an HVAC expert on your architecture, engineering, and construction (AEC) team.