Introducing our new Micro-T cleanroom ceiling grid system

AJ Manufacturing is proud to continue our history of innovation with the introduction of our new Micro-T ceiling grid system for Class 10 to Class 100,000 cleanroom areas. This new grid system is ideal for any ultra-clean manufacturing environment, including industries such as semiconductors, microelectronics, biotechnology, pharmaceutical, medical devices and many others.

Marcus Marchesseault design engineered our Micro-T ceiling grid in-house, along with consulting from Marty Helmus. Marty brings almost 50 years of experience designing and implementing cleanroom ceiling grid systems for the pharmaceutical and microelectronics industries.

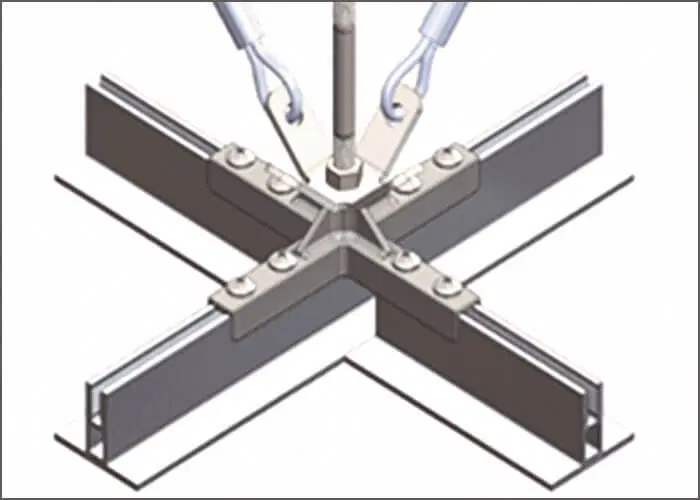

We designed the Micro-T ceiling grid system to carry the load of standard Fan Filter Units, HEPA or ULPA filters, and any required light troffers that may be within the ceiling. Installers suspend the non-walkable system using 3/8″ hanger rod, then assemble it from 2″ (50mm) wide gasket-sealed extruded aluminum tee members, which they bolt together to form a continuous gasketed ledge ready to accept filters, ceiling tiles, or lights. Factory-applied gaskets assure an airtight seal.

Our engineers designed the Micro-T cleanroom ceiling grid system for fast and easy field assembly. We cut the grid sections for a standard 24-1/2″ x 48-1/2″ layout, utilizing a 46-1/2″ length cross tee. We supply the main runner and wall angle in 144” lengths so you can easily cut them to fit your specific requirements.

Our engineering team can quickly determine the number of Micro-T sections needed for your manufacturing space and then provide a fast, accurate, and customized quote. Contact your AJ representative to discuss your individual needs.